Welding Clamps: Product Spotlight

Work smart with magnetic welding clamps

In recent years, an acute shortage of skilled welders has emerged. With a relatively high percentage of welders expected to retire by 2027, it is forecast that the situation will worsen with an estimated shortfall of 36,000 welders by 2027 in the UK.

In recent years, an acute shortage of skilled welders has emerged. With a relatively high percentage of welders expected to retire by 2027, it is forecast that the situation will worsen with an estimated shortfall of 36,000 welders by 2027 in the UK.

As a result, welding shops are looking to make processes more efficient to protect output levels amidst these worker shortages. One of the stages that can make a difference is the choice of clamping method used during the set-up and positioning for welding.

The purpose of a clamp is to hold the workpiece securely and safely, to ensure accurate alignment, and to prevent slippage during welding. Any misalignment or slippage can weaken the weld and cause product failure.

There are many clamping options available, depending on the size and configuration of the workpiece. The most common methods are usually hand-operated clamps such as C clamps, F clamps, twist clamps, pipe clamps, toggle clamps, bench or table clamps, or even locking pliers.

By applying magnetic technology, Eclipse Magnetics offer a range of magnetic welding clamp options that tackle some of the challenges faced by traditional clamping methods.

What are magnetic clamps?

Magnetic welding aids provide a quick, secure, and accurate alternative to traditional clamping methods. High-strength permanent magnets are carefully positioned in a steel casing with a magnetic field holding the adjoining steel sheet or tube in place at the correct angle. The welder can then work hands-free to complete the tack weld. Eclipse offers both switchable and fixed magnet options; each providing instant clamping with quick and easy fine adjustment.

How do they work?

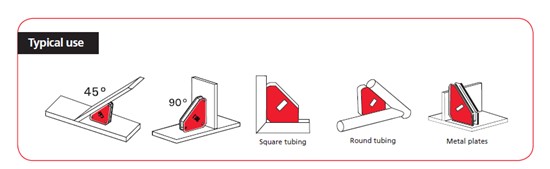

Basic magnetism provides an instant clamping force. The profile of the clamping face means it is suitable for a steel square, round tube, or plate. The holding face angle allows for a variety of inside and outside weld angles. Some options are variable or adjustable to accommodate multiple angles, or some are fixed at 90 degrees. Switchable magnetic clamps are also available, which have a midpoint setting for fine, precise adjustment.

Key Features

The Eclipse range of magnetic welding clamps includes several product options. Depending on the application, the key features are as follows:

- Switchable options are available for easy location and fine adjustment.

- Ideal for clamping round and square tube, angle, profiled, or flat stock.

- Corrosion-resistant, wipe-clean construction.

- Heavy-duty, durable construction

- Feature high-intensity magnets; pull forces up to 200 kg are available.

- Fixed-angle and multi-angle adjustable/variable options are available.

Key Benefits

- Increased productivity: instant, accurate clamping reduces set-up times and improves workflow.

- Allows easy fine positional adjustment and ensures accurate set-up.

- Workpiece access: single-face clamping allows maximum access to the workpiece.

- Maximum safety: high-strength magnets ensure a secure hold with no slippage.

- Simplicity: no need for multiple clamps or complex fixtures.

- Reduced distortion: magnetic clamps distribute the holding force evenly, thereby avoiding distortion, which enables a better weld quality.

Product Variations

Magnetic welding clamps are available in various options. They are suitable for holding workpieces at various angles, including welding corners, joints, or irregular shapes. Options include:

- Switchable quick-hold clamps

- 90˚ Fixed switchable welding clamps

- Inside and outside welding clamps

- Variable-angle welding clamps

- Heavy-duty welding clamps

- Mitre clamps

- Magnetic positioners

- Adjustable clamping links

- Earth welding clamps

Typical Applications

- Maintenance and repair shops

- Steelwork assembly

- Sheet steel fabrication

- Tack welding

- Industrial pipe welding

- Tube or flat section steel assembly

- DIY workshops

To find out more about our magnetic welding aids click here.

UK

UK