Micromag Magnetic Filter

Compact, high-performance grinding coolant filtration systems (flow rates up to 150 litres per min.)

Hello...

Would you like to visit the Eclipse Magnetics US site to view all relevant content for your location?

Magnetic filtration, also known as magnetic coolant separators, allows for fluid to flow around a magnetic rod or core. This high power neodymium magnets attract ferrous particles and removes them from machine coolant fluids, cutting fluids, oils and lubricants. Clean fluid is then returned to the machine, preventing costly repairs and extending the working life of the equipment.

When the magnetic core becomes saturated with ferrous contamination, it can then be easily cleaned either manually or automatically.

Magnetic filtration is the process of separating and removing ferrous contamination from a liquid through the use of a magnet.

The high intensity magnet attracts ferrous (magnetic) contamination. This leads to the contamination sticking to the magnet. The magnetic core can then be removed from the filter, where the ferrous contamination can be cleaned from the magnet.

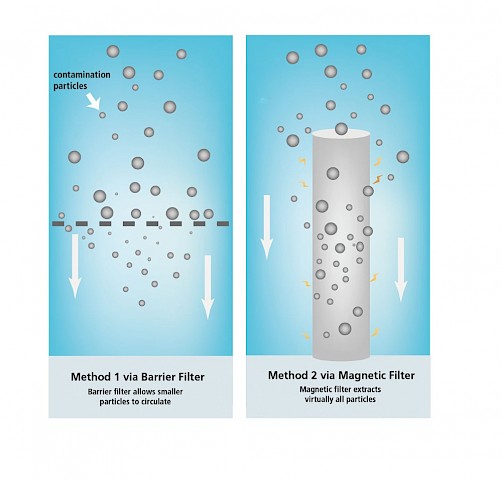

Magnetic filtration systems are highly effective, removing even the smallest particles of contamination. In contrast, with a barrier filter such as a paper filter, the particles may pass through the paper if they are too small. This makes magnetic filters an effective method of removing ferrous contamination from liquids such as coolant, oil or cutting fluid.

Some magnetic filters require manual cleaning, such as the Micromag and Filtramag systems. However, automated magnetic filtration systems are also available, such as Autofiltrex and Automag. These systems are self-cleaning, keeping downtime to an absolute minimum. These systems also enable ferrous material to be reclaimed and recycled.

High-quality neodymium magnets feature in our CNC machine coolant filtration, which are capable of attracting virtually all ferrous contamination, including ultra fine ferrous particles. The advanced magnetic core design creates a magnetic field pattern which ensures that the filters do not block, even in high-contamination applications.

Our design and development team has carried out careful analysis of fluid flow characteristics, ensuring that our range of filters are designed to optimise the fluid flow. As a result, contamination exposure to the magnet is maximised, ensuring extremely efficient collection rates WITHOUT interrupting or reducing the fluid flow delivery to the machine. See how magnetic filters compare to traditional filtration methods.

Traditional barrier filters such as paper media and cartridges are constrained by pore size. If the pore is too big then contamination continues to circulate, but if it is too small it blocks. See below:

We are often asked how our magnetic filtration systems compare to barrier filters, such as paper filters or cartridge filters. Here's a simple comparison:

Barrier Filter

Magnetic Filter

See how magnetic filtration compares to traditional fluid filters or separators

Cleaning magnetic filters is a simple process, and takes just a few minutes.

With our manual clean filter options such as Micromag and Filtramag+, the magnetic cores can be easily removed and scraped clean with a simple cleaning tool. The core is then replaced into the filter, where it will continue to collect ferrous particles.

Alternatively, the Automag Skid and Autofiltrex range of magnetic filters provide fully automated "push-button" filtration options which remove ferrous debris, separate it from the process and reclaim the waste for recycling. This means that no manual cleaning is required, keeping your downtime to an absolute minimum.