A Quick Guide to Magnets, Magnetic Metals & Non-Magnetic Metals

The first magnets were discovered by ancient civilisations back 2,500 year ago. Magnetic compasses were used extensively for navigation in Europe and China during the 12th and 13th centuries AD.

Magnets are important in modern technology. The magnet market continues to grow due to a growing demand for magnet circuit parts widely used in industrial, automotive, scientific and everyday household equipment.

What is magnetism?

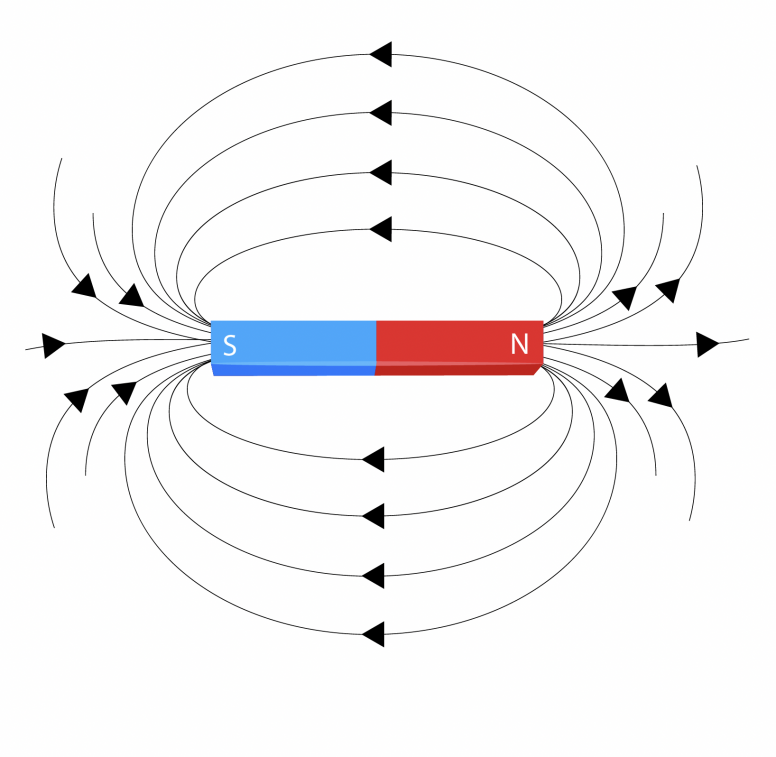

Magnetism can be described as a force that attracts and repels magnetic objects. This force is mediated by magnetic fields that penetrate different media.

Some materials naturally have magnetism as a default property. However, certain materials can be magnetised or demagnetised according to the requirements.

What Creates Magnetism in Metals?

So, what makes metals magnetic? Magnetism is caused by the movement of electrons. It is similar to electric current. When electrons spin, they create a small dipole.

The net force of these spins can be negligible if the spins are balanced. On the other hand, if there are many unpaired elements, then the magnetic moment can become very large. Magnetic fields are created around metals as a result of this process.

The net force of these spins can be negligible if the spins are balanced. On the other hand, if there are many unpaired elements, then the magnetic moment can become very large. Magnetic fields are created around metals as a result of this process.

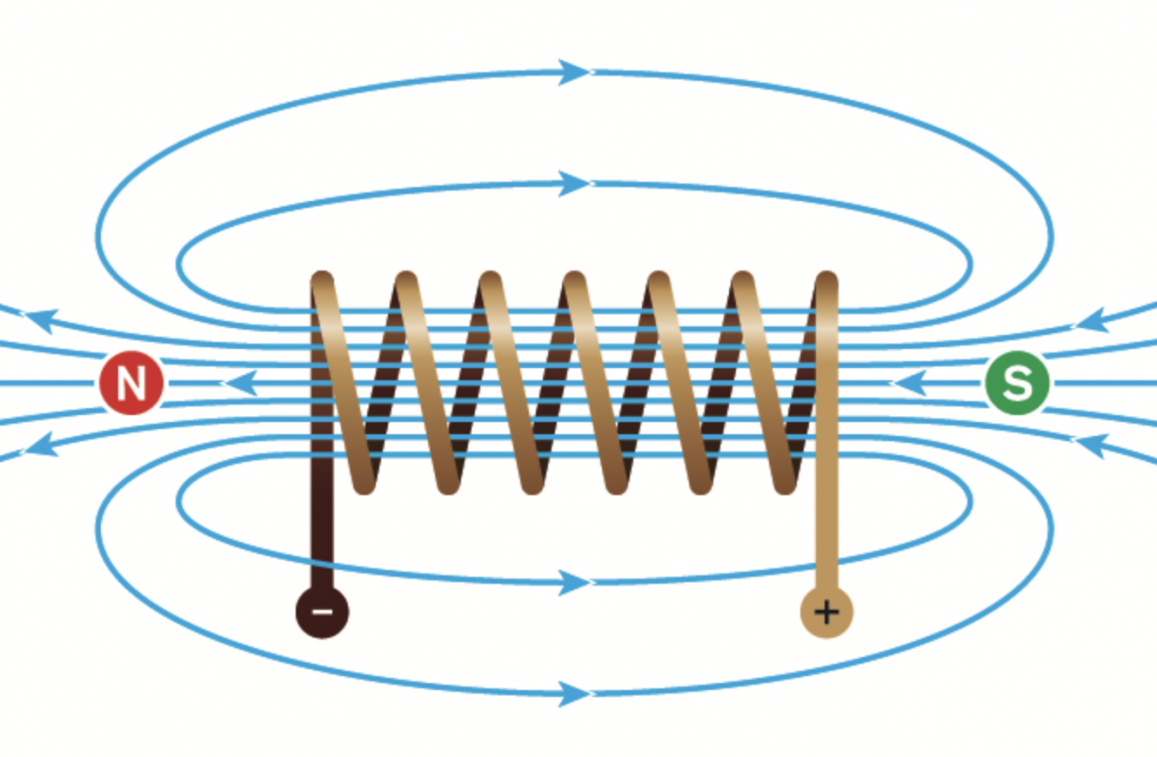

Electric currents can also produce magnetic fields. An electric current passing through a wire creates a circular magnetic field. The magnetic field created by an electric current near a conductor of power can also be used to create electric currents.

It has led to the discovery of many innovative devices and applications that make use of magnetism and electricity. Electromagnetic theories explain so much of modern technological advancement.

What types of magnets are available?

There are many types of magnets. A magnetic metal can be distinguished by how long its properties remain active. As a result, magnets can be classified into the following categories:

- Permanent

- Temporary

- Electromagnets

Permanent Magnets

Permanent magnets come to mind when talking about magnets. A magnetic field can be created by magnetising these objects. As a perfect example, the refrigerator magnet, which commonly hangs notes on the refrigerator door.

Most permanent magnets contain iron, nickel, or cobalt.

Permanent magnets are made from two types: "Hard" and "soft" magnets. Magnetic metals that are "hard" tend to remain magnetised for a long time. The following are some common examples

- Alnico is an alloy made up of aluminium, nickel and cobalt. A strong permanent magnet can be made from Alnico alloys. Consumer electronics and industrial applications use them extensively. The material is found for example in large electric motors, microphones, loudspeakers, electric guitar pickups, and microwaves.

- Ferrite is a ceramic compound composed of iron oxide and other elements (Strontium or Barium). Among the applications of ferrites are refrigerator magnets and small electric motors.

- Neodymium magnet (NdFeB) is a type of rare-earth magnet that is composed of a neodymium, iron, and boron alloys. General Motors and Sumitomo Special Metals invented them in 1982. The strongest permanent magnets currently available are neodymium magnets. Among their applications are cordless tools, hard disk drives, and magnetic fasteners.

- Samarium Cobalt alloys are also rare earth magnets, often used in specialist applications such as aerospace.

The magnetisation of "soft" magnetic metals is possible, but they lose their magnetism quickly. Typical examples include iron-silicon alloys and nickel-iron alloys. Materials such as this are typically used in electronics, for example in transformers and magnetic shielding.

The internal structure of permanent magnets creates magnetic fields. They are usually not prone to losing their magnetism easily. Ferromagnetic metals can be made into permanent magnets that do not lose their magnetic field, regardless of external influences. They can withstand demagnetising forces, and are thus stable.

The internal structure of magnet materials is key to understanding permanent magnets. When domains of a material are lined up in the same direction, they display magnetic properties. Domains are tiny magnetic sources within the structure of a material.

The domains of ferromagnetic material are aligned in strong magnets.

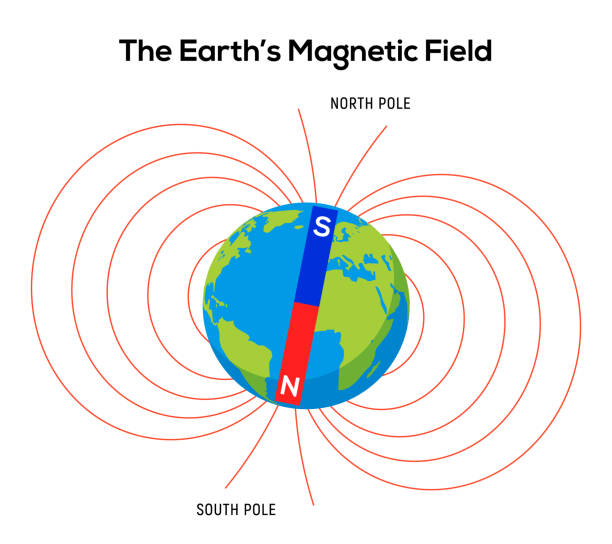

The Earth's core behaves like a permanent magnet because of similar conditions present inside it. But note that the Earth's geographic North pole is actually a Magnetic South Pole.

Temporary Magnets

A temporary magnet is a magnet that acts like a permanent magnet when in a magnetic field, but loses its magnetic properties when out of a magnetic field. Under certain conditions, temporary magnets preserve their magnetic properties. If these conditions no longer exist, the magnetic fields will disappear.

Examples of temporary magnets include soft materials with low magnetic properties, such as annealed iron and steel. In the presence of a strong magnetic field, they become magnetic. Their coercive power is low.

If you've ever seen paper clips stuck together when a permanent magnet is nearby, then you know how it works.

Magnetic fields can cause paper clips to become temporary magnets attracting other paper clips. In the absence of the permanent magnet, the paper clips lose their magnetic properties.

Electromagnets

Magnetic fields are generated by electro magnets as electric current passes through them. Their applications are diverse. As an example, motors, generators, relays, headphones, etc. all use electromagnets.

Electromagnets have a ferromagnetic core surrounded by a coil of wire. By connecting the wire to a source of electricity, a strong magnetic field is created. It is further amplified by the ferromagnetic material. Depending on the electric current, electromagnets can be extremely powerful.

Magnetic force can also be turned on and off with the press of a button. Magnetic force has a number of special properties that we can use for our applications because of this special attribute.

What are Magnets Made Of

Magnets are made of a group of metals called ferromagnetic metals. Nickel and iron are examples of these metals. Metals such as these are unique in their ability to be magnetized uniformly. By asking how a magnet works, we mean how the magnetic field of a magnet works on the object. It is quite interesting to find out what the answer is.

Every material contains several small magnetic fields called domains. It is common for these domains to be independent of one another and to face different directions. However, the magnetic domains of all ferromagnetic metals can align when a strong magnetic field is applied, creating a stronger magnetic field. Most magnets are made in this way.

Magnetic Strength

Which are the strongest magnets?

Rare-earth magnets are the most powerful magnets available today. Strongest among the rare-earth magnets are neodymium magnets. As long as the magnetic circuit is in good condition, samarium cobalt magnets can outperform neo magnets at elevated temperatures (of approximately 150 °C and above).

What could affect a magnet's strength?

Magnet strength can be affected by a number of factors, including:

Temperatures

Radiation

External magnetic fields such as from high currents

A magnet near another magnet (in repulsion)

Corrosion - some magnets need protective coating is necessary to keep them from corroding in high humidity (eg: NdFeB magnets)

In modern magnet materials, shock and vibration have no effect, unless the shocks or vibrations are profound enough to damage the magnet.

Can a magnet maintain its strength forever?

As long as a magnet is stored away from factors that negatively affect its magnetism, such as power lines, other magnets, high temperatures, etc., it will theoretically retain its magnetism forever.

What are some of the metals that are magnetic?

So, which metals are magnetic?

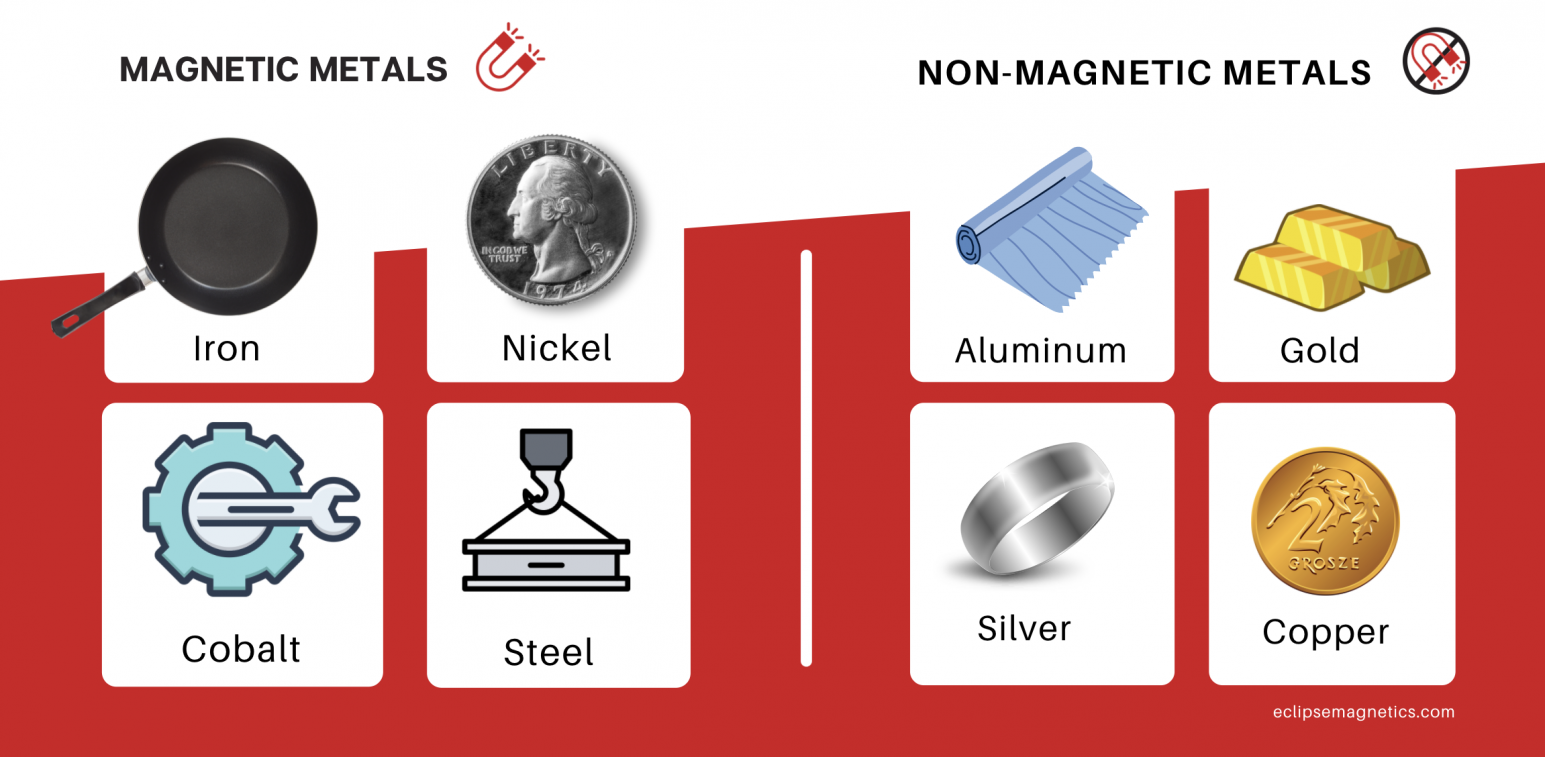

Magnetic fields can interact with metal in a number of ways. It all depends on the material's internal structure. There are three main types of metal interact with magnetic fields including:

- Ferromagnetic

- Paramagnetic

- Diamagnetic

Magnets are strongly attracted by ferromagnetic metals, while the rest aren't. Paramagnetic metals also draw attention to magnets, though they attracted them in a very weak way. Diamagnetic materials, on the other hand, show a weak repulsion when placed near a magnet. Only ferromagnetic metals are considered truly magnetic.

Picture - Magnetic Metals vs Non Magnetic Metals (please note that Aluminium and Copper do interact with changing magnetic fields)

List of Magnetic Metals

Here are some of the most well-known magnetic metals. Some of them are always magnetic. Some materials like stainless steel, however, don't exhibit magnetic properties unless they have a certain chemical composition.

Iron

Ferromagnetic metals such as iron are extremely well-known. In fact, it is the strongest ferromagnetic metal. Our planet receives its magnetic properties from it, and it makes up a substantial part of its core. The Earth therefore functions as a permanent magnet by itself.

There are many factors that contribute to iron's magnetism. In addition to its electron spin at the atomic level, its crystalline structure plays an important role as well. In the absence of this, iron would be a non-magnetic metal.

Depending on the crystalline structure, iron has different properties.

The alpha-FE structure of iron's body-centred cubic (bcc) structure makes it ferromagnetic. Meanwhile, it does not display magnetism in face-centred cubic (fcc) gamma-Fe structures. The beta-Fe structure, for example, exhibits paramagnetic properties.

Picture - Iron filings in a magnetic field

Nickel

Nickel is also a popular magnetic metal with ferromagnetic properties. Its compounds are also found in the earth's core. Nickel has historically been used to make coins. Nickel is used today in batteries, coatings, kitchen equipment, phones, buildings, transportation, and jewellery. Ferronickel, a key component of stainless steel, is manufactured from nickel.

Nickel is also a component of Alnico magnets (made of aluminium, nickel, and cobalt).

Cobalt

Cobalt is a ferromagnetic metal. Over the past 100 years, cobalt has been used widely because of its excellent magnetic properties.

Cobalt can be used to make both soft and hard magnets. Compared to other soft magnets, cobalt-based magnets have a number of advantages. In particular, their saturation point is high, with Curie temperatures within the range of 950...990° Celsius. Therefore, they can be used in high-temperature applications (up to under 500°C).

Cobalt alloys are used in hard disks, wind turbines, MRI machines, motors, actuators, and sensors.

Steel

Due to its iron content, steel also exhibits ferromagnetic properties. Steel is attracted to magnets in most cases. It is also possible to create permanent magnets using steel.

The steel grade EN C15D, for example, contains iron between 98.81 and 99.26%. This steel grade contains a high percentage of iron. As a result, the ferromagnetic properties of iron transfer to steel.

Stainless Steel

Some stainless steels are magnetic and some are not. An alloy steel becomes a stainless steel by adding Chromium to the alloy .The composition and molecular structure results in ferritic and martensitic stainless steels are being magnetic.

Austenitic steels, on the other hand, do not display ferromagnetic properties due to their molecular structure. As a result, it can be used in MRI machines.

It is the amount of nickel that is the main cause of the magnetic difference. The strengthening of the oxide layer improves corrosion protection, but it also alters the structure of the stainless steel.

Rare Earth Metals

In addition to the metals mentioned above, some compounds of rare earth elements are also ferromagnetic. Gadolinium, samarium, and neodymium are all magnetic rare earth metals.

It is possible to manufacture magnets with different properties using the above metals in combination with iron, nickel, and cobalt. Magnets such as these have specific properties needed for certain applications.

For example, samarium-cobalt magnets are found in turbo-machinery and high-performance electric motors.

Which Metals Are Not Magnetic?

In the periodic table, only a few metals are magnetic. Other common metals are non-magnetic. Here are a few of them.

List of Non-Magnetic Metals

Aluminium

The crystal structure of aluminium, like that of lithium and magnesium, makes it non-magnetic. These three materials are all examples of paramagnetic metals.

Despite the fact that aluminium corrosion can occur in a variety of ways, it is known for its resistance to corrosive environments. Combined with its light weight, this makes it a useful metal in many industries.

Gold

Gold is a diamagnetic metal, as are most metals. All diamagnetic metals, including gold, have a weak magnetic attraction to magnets in their pure form.

Silver

Another non-magnetic metal is silver. Diamagnetism makes this metal non-magnetic.

A metal such as silver is known to have the strongest electrical conductivity, thermal conductivity, and reflectivity. When heated, it becomes very soft and malleable. Additionally, it is known for its high corrosion resistance.

Today, it is widely used in the production of jewelry and currency. It is also used in the manufacture of solar panels and water filters.

Copper

The copper itself does not have magnetic properties, but it interacts with magnets in some way (for example: eddy currents). Power plants use this property to generate electricity.

By using this principle, metal detectors can detect non-magnetic metals like gold and silver. However, for most practical purposes, this interaction is insufficient and limits the number of possible applications.

What factors determine the strength of a magnet?

The strength of a magnet can be influenced by several factors:

Material Composition: The type of material used in a magnet significantly affects its strength. For example, magnets made from rare earth metals like neodymium tend to be much stronger than those made from traditional materials like iron or ferrite.

Shape and Size: The shape and size of a magnet also play a role in its strength. Generally, larger and more compact magnets tend to be stronger because they contain more magnetic material and have a higher magnetic flux density.

Magnetisation Process: The process by which a magnet is magnetised can impact its strength. Properly aligning the magnetic domains within the material during the magnetisation process can enhance its overall strength.

Temperature: Temperature can affect a magnet's strength. In many cases, magnets lose their strength at higher temperatures, so controlling the temperature environment can help maintain or optimize their strength.

External Magnetic Fields: External magnetic fields can influence the strength of a magnet, either enhancing or weakening it depending on the direction and magnitude of the external field. Shielding or controlling external magnetic fields can help optimise the strength of a magnet in specific applications.

To optimise the strength of a magnet, you can:

- Choose materials with high magnetic properties, such as rare earth metals.

- Design magnets with shapes and sizes that maximize magnetic flux density.

- Use precise magnetisation techniques to align magnetic domains effectively.

- Control temperature to ensure optimal operating conditions for the magnet.

- Minimise or shield against external magnetic fields that may interfere with the magnet's strength.

FAQs

Can magnets lost their strength over time, and if so, how can this be prevented or mitigated?

Yes, magnets can lose their strength over time due to various factors. Some common reasons for magnetic strength degradation include exposure to high temperatures, physical damage, exposure to external magnetic fields, and aging of the magnetic material.

To prevent or mitigate the loss of magnet strength, several strategies can be employed:

Proper Storage: Store magnets away from heat sources and other magnets to prevent exposure to high temperatures and magnetic fields that could demagnetize them.

Temperature Control: Keep magnets within their optimal temperature range to avoid thermal demagnetization. For permanent magnets, this often means avoiding exposure to temperatures above their Curie temperature, beyond which they lose their magnetic properties.

Protective Coatings: Apply protective coatings or encapsulation to magnets to shield them from physical damage, corrosion, and environmental factors that could degrade their magnetic strength.

Avoid Mechanical Stress: Handle magnets carefully to avoid mechanical stress or impact that could disrupt their internal structure and weaken their magnetic field.

Regular Testing and Maintenance: Periodically test magnets to monitor their strength and condition. Replace or refurbish magnets as needed to maintain optimal performance.

Magnetic Shielding: Use magnetic shielding materials or configurations to protect magnets from external magnetic fields that could interfere with their performance.

Quality Control: Ensure that magnets are manufactured to high-quality standards and specifications to minimize variability in magnetic strength and susceptibility to degradation.

By implementing these measures, it's possible to prolong the lifespan and effectiveness of magnets in various applications.

Are there any safety considerations or hazards associated with handling strong magnets, and how can these be managed?

Yes, there are safety considerations and potential hazards associated with handling strong magnets, due to their powerful magnetic fields. These hazards include:

Pinching and Crushing Injuries: Strong magnets can attract ferromagnetic objects with significant force, posing a risk of pinching or crushing injuries if fingers or body parts get caught between magnets or between a magnet and a ferrous object.

Impact Injuries: If strong magnets collide with each other or with metal surfaces, they can chip or shatter, projecting sharp fragments at high velocity, posing a risk of impact injuries to nearby individuals.

Swallowing Hazard: Small magnets or magnet fragments can be ingested accidentally, especially by children or pets. If multiple magnets are swallowed, they can attract each other across intestinal walls, causing serious complications such as blockages, perforations, or tissue damage.

Electronic Device Damage: Strong magnets can interfere with electronic devices, including pacemakers, credit cards, hard drives, and medical equipment, causing malfunctions or data loss.

To manage these safety hazards when handling strong magnets, consider the following precautions:

Use Protective Gear: Wear gloves and safety glasses when handling strong magnets to protect against pinching injuries and impact hazards.

Handle with Care: Handle magnets carefully to avoid collisions, impacts, and sudden movements that could lead to injury or damage.

Keep Away from Children and Pets: Store strong magnets in a secure location out of reach of children and pets to prevent accidental ingestion or injury.

Use Caution During Assembly: Exercise caution when assembling or separating strong magnets to prevent pinching injuries and avoid sudden movements.

Store Safely: Store strong magnets away from electronic devices, credit cards, pacemakers, and other sensitive equipment to prevent interference or damage.

Educate and Supervise: Educate users about the hazards of strong magnets and provide appropriate training and supervision, especially in educational or research settings.

Seek Medical Attention: In the event of ingestion or injury involving strong magnets, seek medical attention promptly for evaluation and treatment.

By implementing these safety measures and precautions, the risks associated with handling strong magnets can be effectively managed and minimised.

Get in Touch Today

If you would like to discuss your specific magnet needs with our team of experts, why not get in touch today? We offer free consultations to understand your requirements and will tailor a solution suited to your business. Click here to find out more.

UK

UK