Sustainable Filtration: The Environmental Advantages Of Magnetic Systems

In an era defined by ambitious Net Zero targets and the urgent imperatives of the Climate Change Act and the Paris Agreement, industries worldwide are re-evaluating their environmental footprints.

Among these sectors, the machine tool industry stands out, not only for its substantial economic impact—valued at approximately $80 billion annually—but also for its significant environmental footprint. Central to this footprint is the use of metalworking fluids, with an estimated 2 billion litres consumed each year. Raw fluids are often used in dilute form, which means the disposal volumes may be significantly higher.

As industries strive to align with global sustainability goals, magnetic filtration systems are emerging as a powerful ally. These innovative systems promise to enhance operational efficiency while significantly reducing waste and environmental harm, marking a pivotal shift towards more sustainable industrial practices.

How do magnetic filtration systems work?

Magnetic filtration systems use the power of magnetic fields to capture and remove ferrous contaminants from industrial fluids, such as metalworking fluids. These systems typically consist of powerful magnets positioned strategically within the filtration unit.

As the contaminated fluid flows through the system, the magnetic fields attract and hold onto metal particles, preventing them from continuing through the fluid stream. The trapped particles are then collected and periodically removed, ensuring a continuous filtration process.

This method is highly efficient, allowing for the effective removal of even sub-micron-sized particles, which enhances the overall cleanliness and performance of the fluid, reduces wear and tear on machinery, and minimises the environmental impact associated with fluid disposal and replacement.

Find out more: https://www.eclipsemagnetics.com/products/filtration-systems/how-magnetic-filters-work/

What are the environmental benefits of magnetic filtration systems?

The environmental benefits of magnetic filtration systems are significant, including reducing the use of disposable filters, reducing fluid usage, and extending the life of equipment. Let’s take a look at some of the key sustainability benefits of magnetic filtration.

1. Reducing the use of disposable filters with magnetic filtration systems

One of the significant sustainability benefits of magnetic filtration systems is their ability to drastically reduce the reliance on disposable filters. Traditional filtration methods often involve the use of paper, synthetic materials, and other non-biodegradable components. As these disposable filters capture contaminants, they quickly become saturated and must be replaced frequently, leading to increased landfill waste and resource consumption.

Magnetic filtration systems use reusable magnetic elements to extract metal particles from fluids. When used correctly, these magnetic components last a lifetime without any need for consumable replacement parts. They are simply cleaned and returned to service.

By reducing the need for disposable filters, magnetic filtration systems significantly cut down on the volume of waste sent to landfills. This reduction in waste not only conserves natural resources but also decreases the environmental impact associated with the production, transportation, and disposal of disposable filters.

Additionally, the reduction in the use of paper and synthetic materials aligns with broader sustainability goals, minimising the industrial footprint and promoting a circular economy. By adopting magnetic filtration systems, industries can enhance their waste management practices, contributing to a cleaner environment and supporting global efforts to achieve Net Zero targets and other climate action initiatives.

Read more about companies that reduced waste consumption.

https://www.eclipsemagnetics.com/case-studies/dielectric-fluid-protection/

https://www.eclipsemagnetics.com/case-studies/turbocharger-balancing-machines/

https://www.eclipsemagnetics.com/case-studies/fuel-tank-wash-system/

2. Reducing fluid usage

Advanced magnetic filters utilise high-intensity magnets, which enables them to extract ultra-fine ferrous particles, resulting in cleaner, longer lasting fluids.

Traditional barrier-based filtration technology is restricted by the mesh or membrane size. This is typically >10 microns, which allows smaller contamination particles to continue to circulate and accumulate. This gradually reduces the effectiveness of fluids and shortens their effective lifespan. Barrier filters can also have an adverse effect on the fluid’s natural additives, which also contributes to reducing the fluid's life.

When considering all stages of their production, usage, and disposal, metalworking fluids generate a significant carbon footprint during their lifespan. The extraction of raw materials, additives, and energy used in processing, transportation, and ultimate disposal amounts to millions of metric tonnes of carbon emissions each year. In addition to the environmental costs, the financial costs of the replacement and disposal of fluids are a valid consideration. Metalworking fluids are often classified as hazardous, so the disposal costs are relatively expensive.

In some cases, using magnetic filters can extend fluid life by up to 10 times. Increasing the usable lifespan of coolants and cutting fluids can be a significant step in progressing towards net-zero manufacturing.

https://www.eclipsemagnetics.com/case-studies/gear-grinding-honing/

3. Recyclable ferrous waste

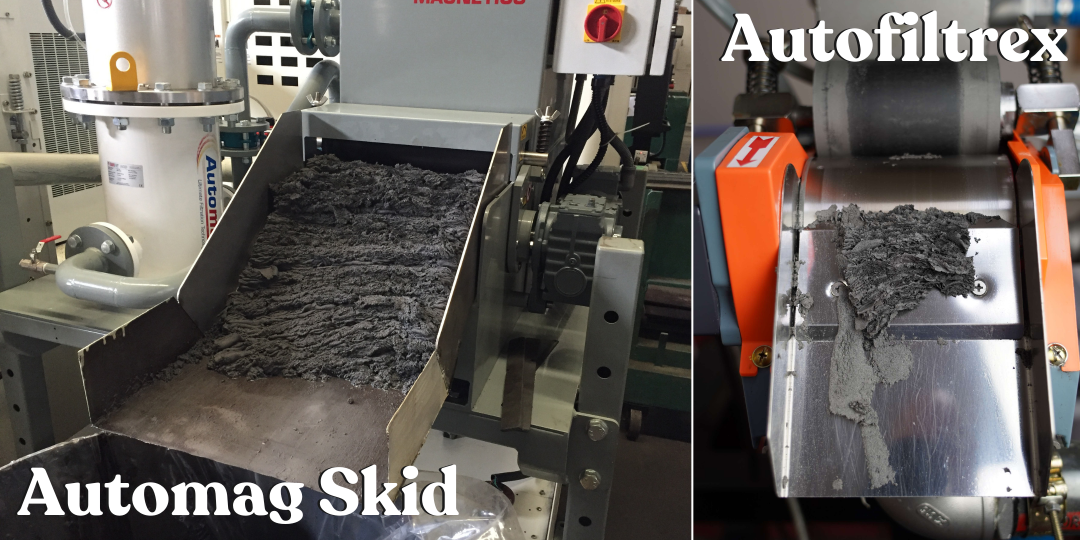

Magnetic filtration systems can be supplied with an integral waste reclaim unit. This separates out the ferrous waste in a relatively dry cake form, which can then be recycled. With traditional filtration methods, the waste by-product is an unrecoverable fluid-contaminated sludge, which is impossible to separate from the bag or cartridge media.

It is estimated that the production of metals accounts for 40% of all industrial gas emissions. The International Energy Agency also estimates that producing 1 ton of steel generates 1.4 tons of CO2 emissions. Magnetic filtration can help recycle raw materials and contribute to reducing the CO2 burden.

https://www.eclipsemagnetics.com/case-studies/steel-pipe-forming/

4. Increased tool and machine life

By removing virtually all ferrous particles from metalworking fluids, magnetic filters ensure they run cleaner for longer. This reduces the abrasive wear and friction generated by the build-up of particles in the fluids.

As contamination builds up, it has an abrasive effect on the cutting tool and can cause blockages in fluid delivery channels, increasing the risk of premature tool wear or drills burning or breaking. It can also damage machine components such as pumps. Magnetic filters help protect equipment from abrasive wear and, in doing so, help reduce scrappage and waste.

https://www.eclipsemagnetics.com/case-studies/brake-disc-grinding/

https://www.eclipsemagnetics.com/case-studies/deep-hole-drilling/

https://www.eclipsemagnetics.com/case-studies/steel-bar-drilling/

https://www.eclipsemagnetics.com/case-studies/camshaft-grinder/

https://www.eclipsemagnetics.com/case-studies/tool-manufacture/

5. Reduced product rejects

Magnetic filtration has been proven to significantly improve the surface finish of components in some cases. This is particularly relevant for precision components where surface finish tolerances are very demanding. With traditional barrier or membrane filters, smaller ferrous particles continue to circulate in the coolant. When there is a high concentration of fine particles, this can have an abrasive or frictional effect on the workpiece and lead to minor defects on the product surface. The particles can also hinder the accuracy of contact between the cutting or grinding tool, which can adversely affect cutting accuracy.

There is a greater risk of finished products not conforming to demanding quality standards and being scrapped, therefore adding to the waste stream. Powered by high intensity magnets, magnetic filters remove even the finest particles, reducing the risk of damage to the finished product and minimising scrappage.

https://www.eclipsemagnetics.com/case-studies/cutting-tool-grinding/

https://www.eclipsemagnetics.com/case-studies/bearing-super-finishing/

6. Minimal energy usage

Advanced magnetic filters are powered by permanent Neodymium magnets. These ensure high-performance filtration capability with no sustainable energy source required*. If used in the right operating conditions, the magnetic field does not diminish over the lifetime of the product.

7. Committed to Net Zero

Advanced magnetic filters are produced by Eclipse Magnetics, a company committed to being a “Net Zero” manufacturer by 2040. Eclipse Magnetics is striving to ensure that their manufacturing processes and product components have a minimal net effect on the overall carbon footprint.

They have a continuous programme to reduce on-site emissions, developing low emission products, working with suppliers committed to Net Zero, and supporting their employees with greener business travel. The programme has already yielded a 32% reduction in C02 emissions.

*Automated magnetic filters require a minimal electricity supply.

Prioritise sustainability with our magnetic filtration systems

Our range of magnetic filters includes the manual-clean Micromag and Filtramag+ models, suitable for flow rates ranging from 70 to 500 litres per minute. The filtration range also features automated clean units, which are ideal for 24/7 operations. The Autofiltrex provides a cost-effective automated option, and the Automag Skid has an integral separation and reclaim unit, and is ideal for high-volume processes.

To find out more about Magnetic Filtration systems, click here, or if you would like one of our team members to visit your site and assess your filtration, contact us.

UK

UK